Бесшумный погружной насос из высококачественной нержавеющей стали отличается компактной конструкцией, высокоэффективным двигателем и системой снижения вибрации для бесшумной работы. Изготовленный из коррозионно-стойкой нержавеющей стали, он обеспечивает постоянный поток воды и длительный срок службы.

предмет номер :

TYЗаказ (Минимальный заказ) :

1Оплата :

Alipay Paypal westernunion T/T L/CПроисхождение продукта :

ChinaЦвет :

CustomizedПорт доставки :

shanghai shenzhen guangzhouВремя выполнения :

please contact 504893184@qq.com or CP +8613696510409Упаковка :

CustomizedМатериал :

SteelРабочая температура :

Fluoroplastic material:-20 to 200 ℃; Engineering plastic material:-20 to 80 ℃ ;Stainless steel material:-20 to 200 ℃ .Рабочее давление :

1.6 MPaБесшумная высококачественная нержавеющая сталь Погружной насос

Погружной насос TY разработан в соответствии с национальными стандартами. В зависимости от условий эксплуатации глубина погружения составляет от 1 до 8 метров. Основная часть насоса находится в жидкости. Преимуществами насоса являются широкий диапазон коррозионной стойкости, высокая эффективность, безопасная и надежная конструкция соединения вала, удобство демонтажа и т.д. Насос можно перекачивать без долива жидкости. Осевая и радиальная силы, возникающие при работе насоса, воспринимаются подшипниками качения и подшипниками скольжения соответственно, что обеспечивает бесшумную работу.

Преимущества продукта

1. Детали проточной части, включая корпус насоса, крышку и рабочее колесо, изготовлены из высококачественной нержавеющей стали, фторопласта и конструкционного пластика, что обеспечивает исключительную долговечность.

2.Насос не имеет уплотнения вала, в нем используются подшипники и втулки из графита, ПТФЭ и других современных материалов, что значительно продлевает срок службы.

3. Насос может работать без предварительной заливки жидкости, работает на глубине до 8 м ниже поверхности жидкости и не требует отдельной смазки или охлаждающей воды, тем самым снижая общее потребление энергии.

Применение продукта

Бесшумный погружной насос из высококачественной нержавеющей стали широко используется в таких отраслях промышленности, как нефтяная, химическая, производство щелочей, плавка, переработка редкоземельных металлов, производство пестицидов, красителей, фармацевтика, производство бумаги, гальваника, электролиз и электроника для транспортировки сильно агрессивных жидкостей.

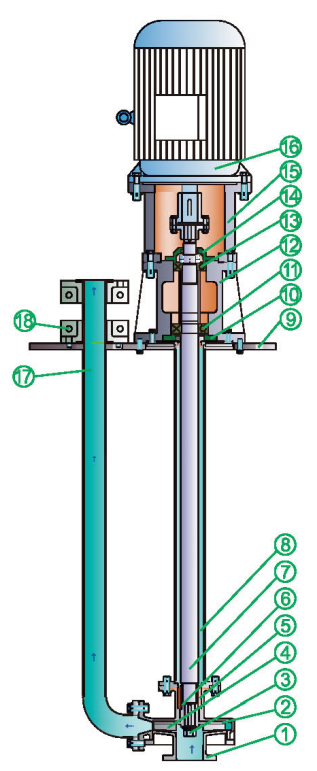

Список материалов

| Часть | Материал | Часть | Материал |

| ① Корпус насоса | 304/316/316L | ⑩ Передний сальник подшипника | ХТ200 |

| ② Крышка насоса | 304/316/316L | ⑪ Передний подшипник | Гкр15 |

| ③ Гайка крыльчатки | 304/316/316L | ⑫ Подшипниковая коробка | ХТ200 |

| ④ Рабочее колесо | 304/316/316L | ⑬ Задний подшипник | Гкр15 |

| ⑤ Втулка вала | ГРАФИТ/SIC | ⑭ Задний сальник подшипника | ХТ200 |

| ⑥ вкладыш вкладыша | ПТФЭ | ⑮ Кронштейн | ХТ200 |

| ⑦ Главный вал | 304/316/316L | ⑯ Мотор | Индивидуальный |

| ⑧ Магистральный трубопровод | 304/316/316L | ⑰ Водосточная труба | 304/316/316L |

| ⑨ Квадратная тарелка | A3 | ⑱ Выходной фланец | ХТ200 |

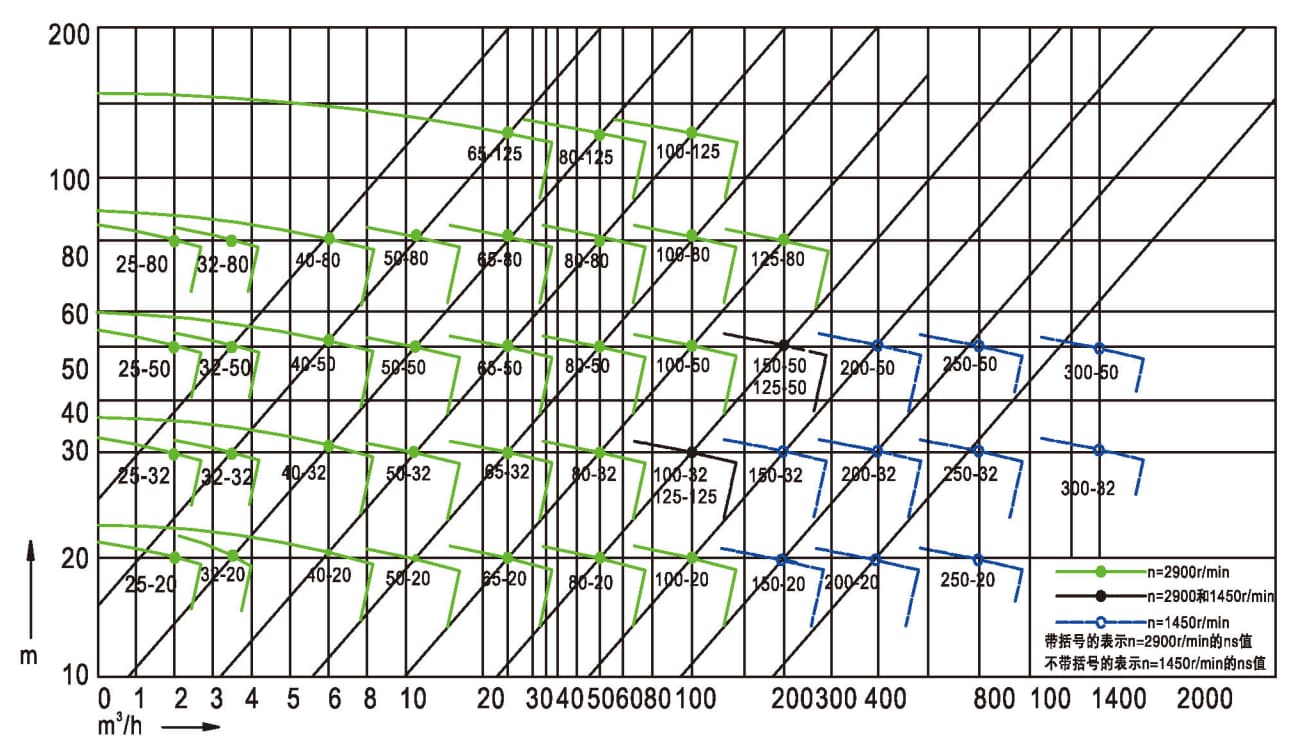

Диапазон производительности

Диапазон производительности:

расчетное давление: 1,6 МПа; Расход: 1,5~

1000 м³/ч;Высота: 15~125 м;Мощность: 2,2~185 кВт

Применимая температура:

①фторопластовый материал: -20~120℃ (кислотно-щелочная среда любой концентрации);

②Конструкционный пластик: -20~80℃(разбавленная кислотная и щелочная среда);

③Материал из нержавеющей стали: -20~200℃(щелочная среда).